Development Prospects of Plastic Building Formwork

With the strength of the country and the gradual improvement of science and technology, the country's requirements for infrastructure have also increased. The experience of many countries proves that it is an inevitable trend of economic development and social progress. The progress of the construction industry not only requires the quality and function of buildings to be perfect, but also its beauty and harmless human health. This requires the development of multifunctional and efficient new building materials and products. Only in this way can we meet the requirements of social progress.

The use of new building materials and products can significantly improve the function of buildings, increase the use of buildings, increase the seismic resistance, facilitate mechanized construction and improve construction efficiency, and reduce construction costs under the same circumstances. Therefore, people's calls for new building materials are getting higher and higher.

The three traditional raw material formwork have failed to meet the increasing quality requirements of the current construction industry:

1. The wood formwork is the mainstream. The wood formwork consumes a large amount of wood, and the scrap residue value is low. Deforestation is required, which is against the protection of the forest as advocated by national policies, and it is necessary to brush release agents during use.

2. The Aluminium Formwork has appeared in the past two years, and the cost is high. It is mainly leased, and mold release agents are also used.

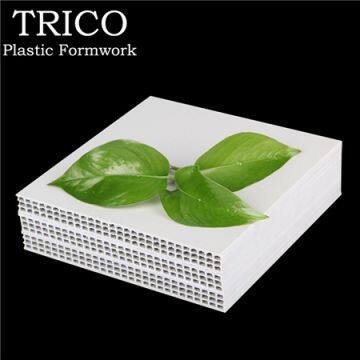

3. The emergence of the combination of hollow plastic formwork and aluminum frame, the cost is lower than aluminum formwork, no mold release agent, easy to recycle, the operation model is the same as aluminum formwork, mainly lease.

Plastic Formwork

The development prospect of Plastic Formwork:

Plastic building templates have been used since the mid-1960s, and Japan started to use ABS resin to make plastic templates, which has a history of more than 50 years. In recent years, plastic templates have developed rapidly in Europe, America, Korea, and Japan. Plastic templates have gradually replaced bamboo, wood plywood, and steel templates, and they have gradually evolved into steel-framed and aluminum-framed plastic templates.

In China, only in the early 1980s did companies and research institutions focus on and develop plastic building templates. In recent years, with the advancement of science and technology, plastic building formwork has been developed and produced in China and has developed rapidly. Therefore, plastic formwork has broad development prospects.

At present, the construction plastic formwork combined with the Construction Formwork Tie Rod has also been initially applied in construction engineering and bridge engineering and has achieved good results. The plastic formwork is used in the construction of bridges, tunnels, and other municipal projects, as well as in construction projects to provide theoretical support and product support. At the same time, it can also solve the problem of concrete formwork in wet, chloride-salt-eroded environments such as sea-crossing bridges and subsea tunnels, laying key technical support for civil engineering construction for entering the marine blue economy.

Architectural plastic formwork is not only a technological innovation, but also a pillar in the construction industry. Therefore, the use of plastic formwork is one of the future development directions of the Chinese formwork industry.

Recently Posted

-

Hot Sale Formwork Steel Prop Screw Sleeve/ Prop Sleeve

September 17, 2020Steel prop is used for your formwork supporting. It has different diameter and adjustable length. Common dia are D60mm a Read More

Read More -

Application of Plastic Formwork in the Industry

September 17, 2020When Plastic Formwork is installed horizontally, try to measure the plastic formwork with a steel ruler, nail 3-4 small Read More

Read More -

What Should I Do If the Scaffold is Rusted?

September 17, 2020The various uses of Scaffolding U Jack are indispensable in our lives. With the development of many aspects nowadays, th Read More

Read More -

Safety Knowledge for Scaffolding

September 17, 2020The quality and stability of the scaffolding directly affect the safety of the construction workers. In order to ensure foolproofn Read More

Read More